Services

APPI can support medical requirements whether through traceability, inspection controls, Performance, Operational or Installation Qualifications, Statistically acceptable inspection methods, PFMEA Analysis, Risk Assessments and other verifiable processes. We enjoy supporting our medical customer’s quality requirements to pass on the necessary assurances their industry requires.

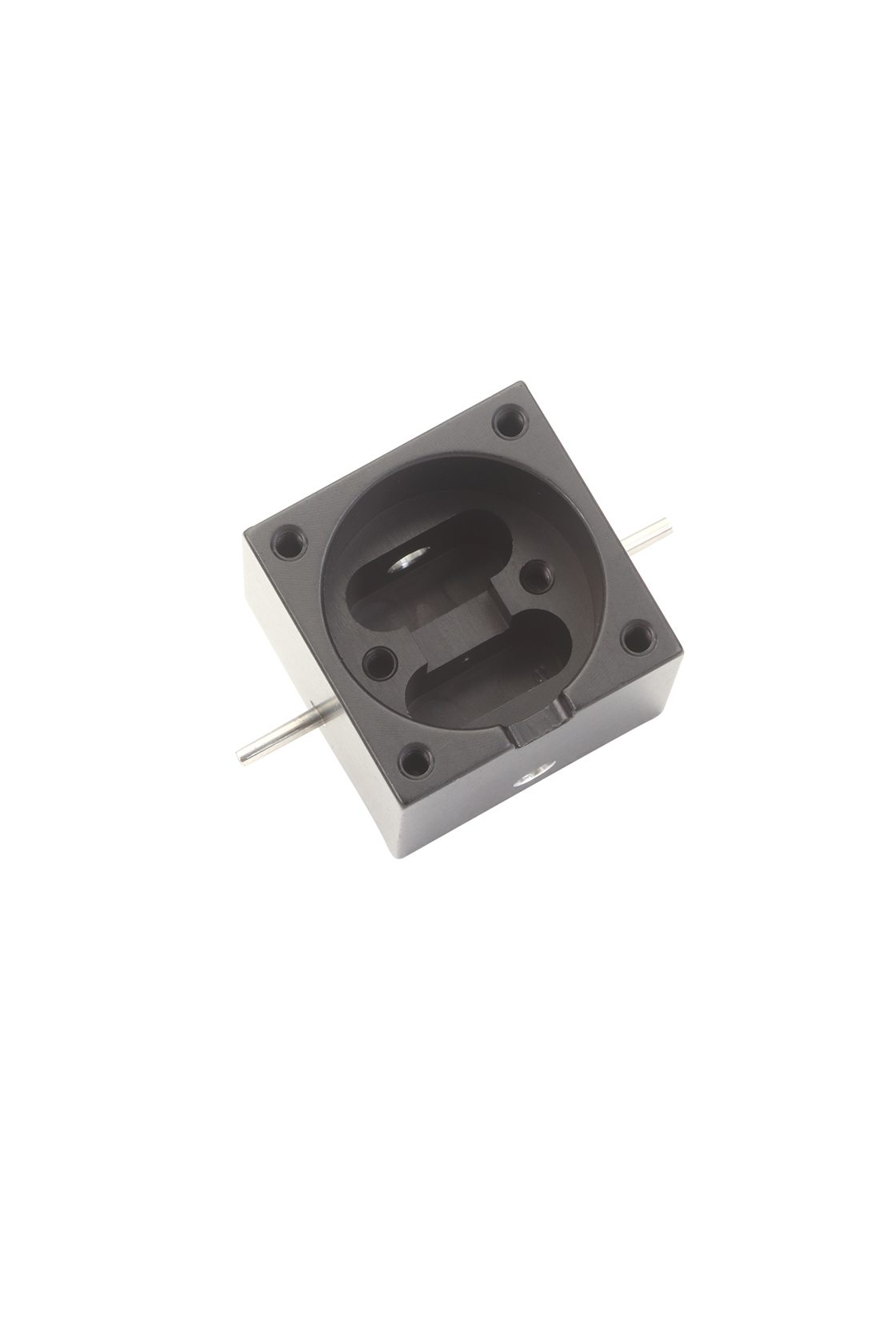

- Machining

- Milling 3 to 5 Axis Horizontal and Vertical

- Lathes

- 8 Axis and Swiss

- EDM

- Wire and Sinker

- Sheet Metal Fabrication

- Laser

- Punches

- Press Brakes

- Tube and Probe Assemblies

Numerous secondary processes and services:

- Plating

- Painting

- Assembly

- Grinding

- Sawing

- Heat Treat

- Ultrasonic Cleaning

- Swaging

- Plasma Coatings

- Vacuum Brazing

I’m happy to report that with the last group of conversion to kanban, APPI has become the first supplier from our Built To Install implementation project plan to be 100% on kanban. Congratulations to APPI on achieving this milestone. Thank you for your support and helping us make our conversion to BTI successful.

-Carlos F., Beckham Coulter Inc.

Most of our communications lately have been schedule changes, but it’s important to share the resulting success of our efforts thus far. Beckman Coulter has been able to meet the notable increases to a few instruments and this would not have been possible without the adjustments you made. Thank you and your team for your continued support.

Mark G., Beckman Coulter Inc.

Excellent job, much appreciated. DTx was in a RUSH for these new jobs and wanted to show their appreciation for how quickly APPi responded to their need.

Doug V., DTx Inc.

Thank your meeting our delivery date for DePuy Synthes. You were a real pleasure to work with.

Linda, DePuy Synthes (now owned by Johnson & Johnson)