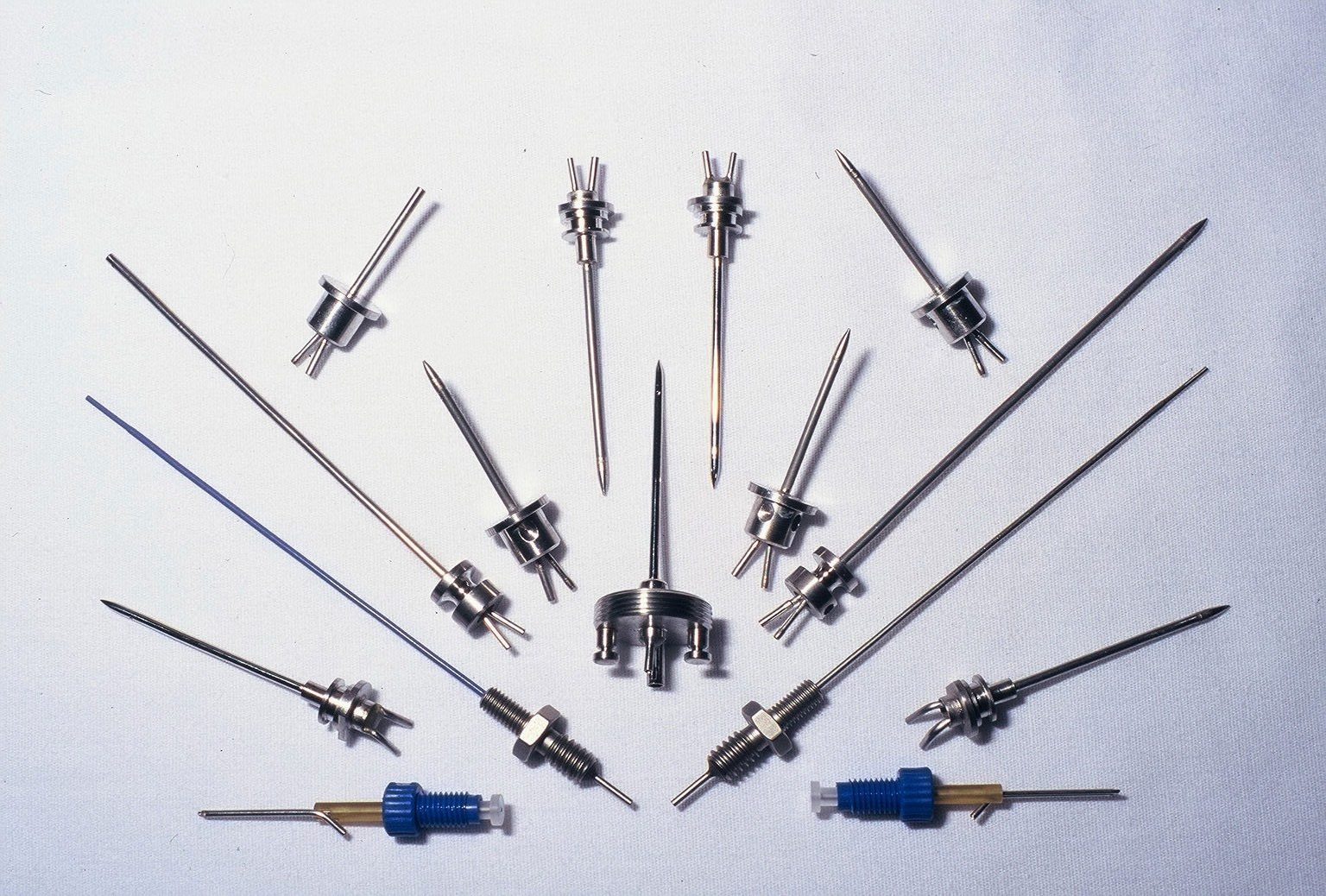

Types of Equipment

Quality and compliance standards for Probe and Tube assemblies start with our specially trained personnel. We have the capability, knowledge, and expertise to support probe and tube projects from start to finish. Specialty processes such as forming, swaging, EDM machining, brazing, heat treating, polishing, micro-blading, lapping and ultrasonic cleaning are routine at our facility. Product assembly is performed to drawing specifications in well-lit areas under high magnification.

Download Complete Equipment List